Adhesive Overwatch

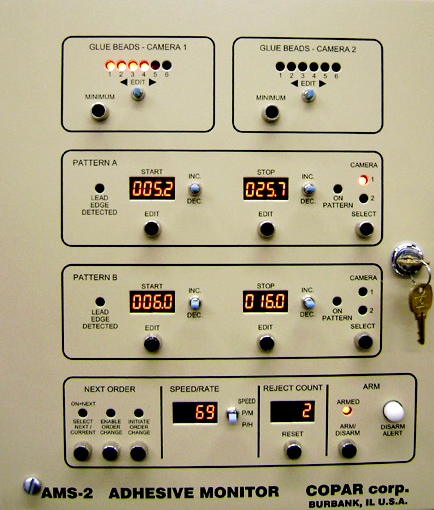

COPAR AMS-2 Adhesive Monitoring System

Keep bead patterns consistent and clean

The COPAR Model AMS Adhesive Monitor System verifies glue patterns applied to cartons, by electronically controlled glue extruders on Flexo folder-gluers. The system uses infrared cameras for single or dual pattern recognition. COPAR custom camera brackets allow easy changeover for “top-down” or “bottom-up” glue pattern monitoring. After desired glue pattern dimensions are entered and corresponding camera(s) selected, analog circuitry samples and stores data from the first glue pattern scanned by a camera immediately after the system is armed. The stored data is used as a standard to compare each subsequently scanned glue pattern applied during a production run. Any carton with a glue pattern failing to meet the standard and/or minimum bead requirement will be counted and marked for removal, while an alarm sounds to alert operators. When a preset number of consecutive cartons are counted, feed interrupt and machine stop are activated. Use of the COPAR model AMS-2 Adhesive Monitor System ensures 100% inspect ion of adhesive application on even the highest speed Flexo folder-gluers. Any variation from a pattern standard-length, position, absence, relative quantity, skips or bead requirement will be detected. Detection of improper adhesive application will reduce waste, customer complaints and network cost.

Features

· Enable or disable editing of acceptable minimum bead selection at the front panel

· Set bead display to be viewed in real time or latched mode

· Enable or disable reject count reset push-button on the front panel

· Enable or disable feed interrupt before a machine stop

· Set system for single or dual camera operation

· Set limits on the recognition area of the bead pattern at camera 1 and camera 2

Contact our Sales Department for more information